|

|

|

I know I will get emails if I don't answer this question here.

What soldering equipment do I use on my workbench?

|

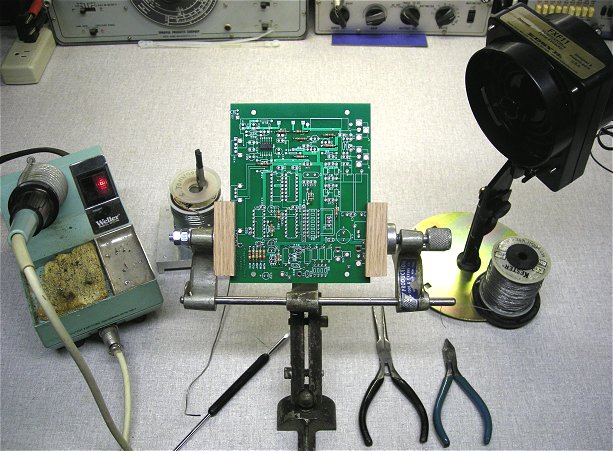

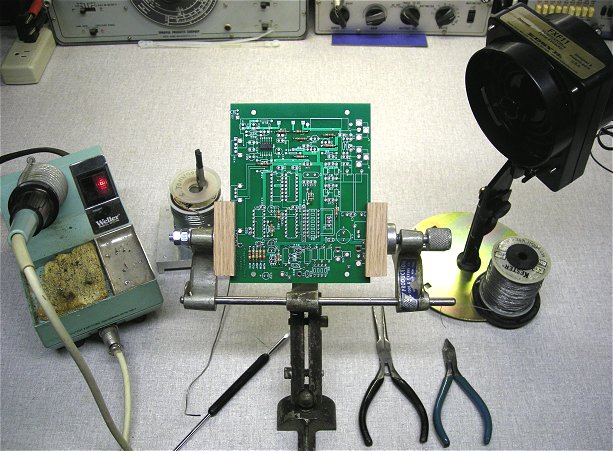

My Analog Bench Set-up

For working on vintage equipment, assembling or repairing through hole circuit boards, etc..

Weller WTCPN Soldering Station, Vintage Circuit Board Holder, various hand tools, and an Edsyn FXF11 Fume Extractor.

|

|

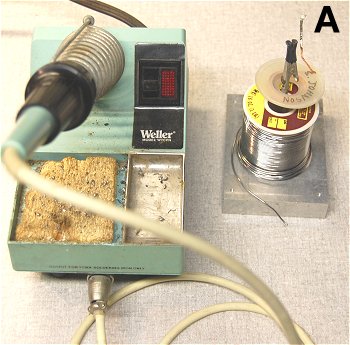

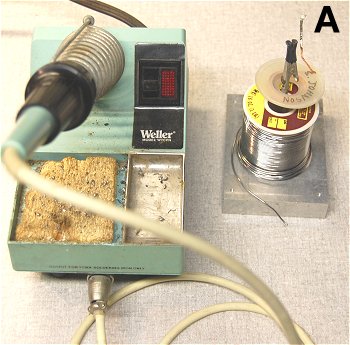

A - Weller WTCPN Soldering Station

I have used this Weller station for 30+ years.

It's been through hell and back and works as good as the day I bought it (used!).

I've replaced the connector, a few tips, and sponges over the years but this Weller station still gets daily use and does not

let me down.

Although I work on mostly vintage electronics, surface mounted components are becoming more popular so I have added a hot air

rework station station (below).

I cobbled together a solder holder that's tall enough to hold a 1 pound roll of solder and a roll of solder wick (for de-soldering).

The alligator clip on top comes in handy for holding a wire steady or as a simple heat-sink.

|

|

B - Weller 8200 N Soldering Gun

I have a few of these and keep one in each shop. It's dual heat and size makes it great for heavy duty electrical work when I need

more heat than my soldering station will generate.

I also use one with a cutting tip for cutting nylon rope. It makes clean cuts and melts the strands together to prevent fraying.

|

|

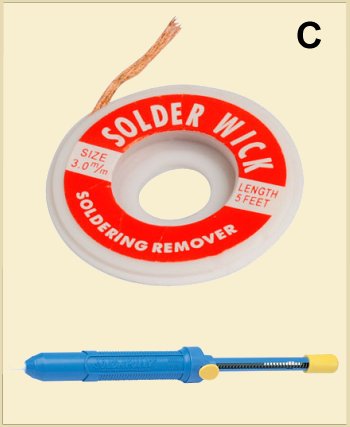

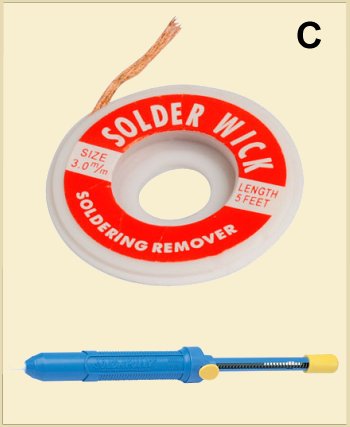

C - De-soldering tools (Solder-Suckers)

A Solder-Sucker and a roll of copper braided solder-wick come in handy for removing excess solder left by me or others, or removing

solder from component leads and circuit boards.

If you have the funds, a desoldering gun makes desoldering components from a circuit board easy.

Check out the Hakko 808 desoldering gun below.

|

|

D - Weller WP-40 Soldering Pencil

This 40 watt Weller is perfect for use in my portable tool cases. Heats up in a minute or so and I use a short piece of

½" copper pipe to slide over the shaft and tip so it can safely

be put back in the tool case right after use.

|

|

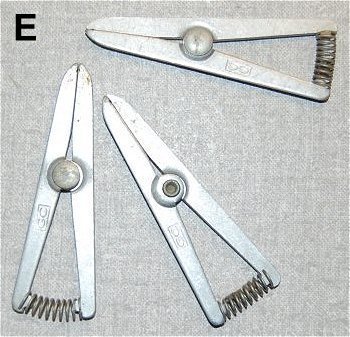

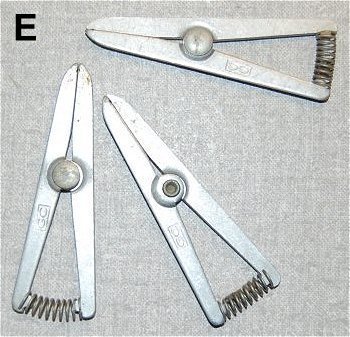

E - Heat Sinks

These heat sinks clip on sensitive components like transistors . They are placed on the lead between the component being soldered

and the soldering point

to help prevent overheating and destroying the component when it's soldered or unsoldered from a circuit board.

|

|

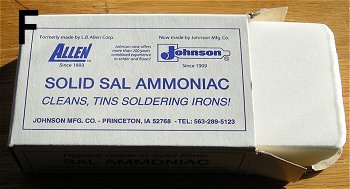

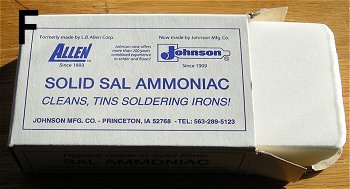

F - Sal Ammoniac Block

Solid Sal-Ammoniac is used for re-tinning soldering tips. Using one of these blocks may help re-tin an iron tip that's in poor

condition and prolong the tips life.

Caution must be used to make sure no residue remains on the tip as Sal-Ammoniac may corrode some electronic component leads and

circuit board runs. I use it as a last resort.

|

|

|

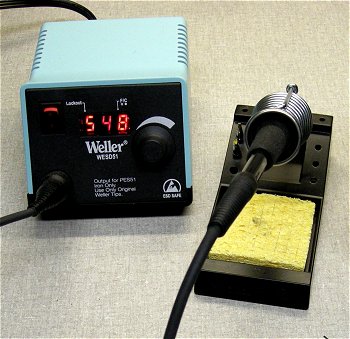

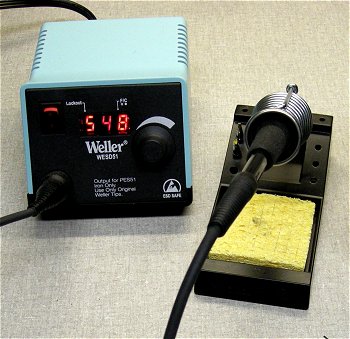

Weller WESD51 Digital Soldering Station

For soldering work where I need to vary the tip temperature I use this Weller controlled temperature soldering station.

I prefer to have a single knob to control the temperature. Buttons can be a pain if you need to change temperatures often.

|

ESD Safe Soldering Workstation

This ESD (ElectroStatic Discharge) safe soldering station I put together includes an inspection microscope with a USB camera

for working on small surface mount devices (SMD) and ESD safe soldering, desoldering, and hot air tools.

Building A ESD Safe Soldering Work Station

|

|

|

Weller WX2 Soldering Station

I use this Weller WX2 soldering station for working with surface mount devices.

It's programmable using it's touch screen or USB port.

The WXMP pencil soldering iron has a small enough tip for detailed work and the

controller also has plenty of power for an iron (up to 200 watts) and a pair of

SMD tweezers for surface mount devices.

Larger Photo

|

|

X-Tronic 6040 Rework Station

This X-Tronic model 6040 Rework Station is for removing and installing newer surface mounted devices and

integrated circuits. It combines a hot air gun and a 60 watt soldering iron in one unit with digital heat controls and a separate

display for temperatures of each.

Airflow for the hot air gun is controlled by a knob. The hot air gun's heater shuts off automatically when it's set back in the

cradle and the blower in the gun runs until it's cooled down.

|

|

Hakko 808 Desoldering Gun

Not sure how I ever got along without this for thru-hole circuit board work. Place the tip over the component lead and pull the trigger.

The component will fall out of the board. It does not plug up and the chamber on top and is easy to empty. Get a couple

different size tips and cleaning tools with it. The optional holder is handy but not necessary as the gun

will lay flat on the bench.

The kit comes with spare filters and a 1 mm tip (most popular size) but it works best if you have a good fitting tip. I also purchased .8, 1.6, and 2.3mm tips along with the cleaning tool for each size.

If you have a board with components on both sides I recommend you get the long 1 mm tip also (my favorite).

The only thing I don't like about the Hakko 808 is it's always on when plugged in. This is a pain if you want to keep it plugged in to bench power. The trigger only operates the vacuum pump.

I added a in-line switch to the cord to eliminate this problem.

Short Video (not mine)

Short Video (not mine)

|

|

Things that make soldering easier

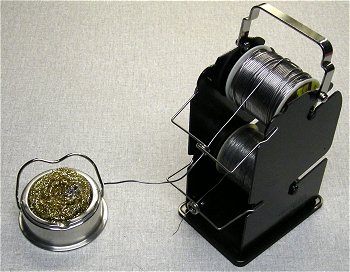

The Aoyue brass wool tip cleaner (left) is a great way to keep your tips clean. This one has a nice metal base with a handle

that can double as a iron holder. It's better better for the tip than a wet sponge. It won't cause the plating on the tip to crack reducing tip life.

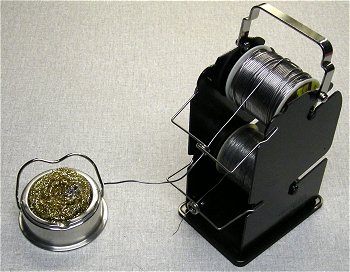

Hakko model 611-2 Dual Solder holder (right) - I never thought I'd use one of these but it comes in handy when I'm using two different solder gauges

for a project. I keep the larger gauge roll that I use the most on top so when the bench gets crowded I can easily grab it.

|

|

Bench Vise

This small "Fractal Vise" has up to eight contact points and is great for holding round and odd shaped components steady for soldering on the bench. Better than a flat jawed vise that could put too much pressure on a component.

On the expensive side but worth it if it's machined well like this one and has the adjusting screws so the moving parts don't bind.

Larger Photo

|

|

Weller Portasol P2KC Portable Butane Soldering Iron

I love this thing. Self ignites and heats up in a couple of seconds.

Has a nice case with an assortment of tips and fits perfect in the bottom of my tool kit.

Larger Photo

Photo - On

|

Don't forget to check out my collection of early vintage soldering irons and soldering guns:

My Soldering Iron and Soldering Gun Collection

|

|