|

|

|

Soldering Stations

This category is for any soldering iron

that has a separate power supply, transformer,

temperature control, or plugs into any type of base.

|

Soldering Station Patent

In December of 1926 William Alferink filed a U.S. patent for a

"Combined Holder and Automatic Circuit Breaker for Electric Soldering Irons".

On July third, 1928 his patent was granted.

This is the earliest patent I have found directly relating to temperature controled soldering stations.

View Patent

|

C & E Marshall Co.

Electric Soldering Machine

|

This early electric soldering machine used a pencil carbon and copper tweezers to pass current through the item being soldered. The large transformer housing has five levels of voltage selected by the large knob and brass contacts on the front.

Current is turned on and off using screw contacts inside the spring loaded wooden foot pedal. The pencil carbon shown in the holder is not original but it fits exactly so I am guessing the original would have been similar.

It was manufactured by the C & E Marshall Co., Chicago sometime after 1922 as there is a patent date on the nameplate of August 15, 1922. I have not found any additional information on it.

Larger Photo

Control Unit

Nameplate

|

|

Bell Telephone Wall Mount Soldering Station

This unique wall mount soldering station was made for Bell Telephone by Vulcan Electric Heater Corporation, New York.

It has two removable soldering irons. The technician would remove and use one until it cooled and

then put it back and use the second iron while the first iron reheats.

The switch at the top turns on the station and the lamp underneath the switch indicates the irons are heating.

Both irons have a two conductor post on the back of the handle that makes contact with the AC supply when they are snapped in

place.

The irons are a little over 16 inches in length. The station is about 27 inches high and 8 inches wide.

Larger Photo

Side Photo/clamp

Larger Photo - Irons

Vulcan Brochure

|

|

Esico Model 5

Soldering Iron Temperature Control

This Soldering Iron Temperature Control regulated any electric soldering iron by plugging the iron into the base and placing tip into the hole in the housing.

A metal strap would then heat and expand breaking an electrical contact in the base.

The temperature was controlled by adjusting a screw to move the contact closer or further from the metal strap.

Larger Photo

Badge

Inside

1940 Patent

|

|

American Beauty Model T-6

Micro Soldering Iron

I will classify this small soldering iron as a soldering station as it has a transformer housed in a small (2"x2"x3")

metal housing with a 12 position switch to select different transformer taps for temperature. the tiny 6" iron is made by Oryx of England.

It is an interesting unit but due to the low power, it is only good for tiny soldering jobs.

Larger Photo

Temperature Scale

|

|

"Flash" Transformer Powered Soldering Iron

It looks like the transformer housing is home made but the system came with two gun type soldering irons an there is a 1946 advertisment below that lists transformer powered irons.

Unfortunately one did not survive shipping in tha same box as the transformeer.

Flash Soldering Irons were manufactured by the Baker-Phillips Co of Minneapolis in the 1940s. The "Flash" name might be derived from their ray-gun looks. Or maybe they just heat quick.

The only markings I can find on these is the "Flash" name on the irons.

Larger Photo

Flash Soldering Iron

Inside Housing

1946 Ad

Damaged Iron (why you don't use newspaper as packing material)

|

|

Weller's First Soldering Station

The Weller W-TCP Soldering Station

This is the first in the series of the Weller model W-TCP soldering stations. It uses an early 24 volt TCP-1 "Magnastat" iron. Magnastat tips controlled the temperature and were available in various temperatures.

The transformer is enclosed in the steel case and the TCP-1 iron is uses screw terminals for connection.

The AC cord is hard wired into the case.

Larger Photo

Magnastat Patent

|

|

Weller W-TCP Soldering Station

This black Weller model W-TCP was Weller's second soldering Station (around 1967). It's 60 watts and used a 24 volt Weller TCP 1 Magnastat iron which was connected to terminals on the top right side of the power supply.

Weller's next version of the W-TCP was green and the iron was connected internally through a hole in the base on the left side. A power switch and light were added to later versions like the WTCP-L (below).

This one is still works well after 46 years.

Larger Photo

Name Plate

Service Bulletin

All things Weller in my Collection

|

|

Weller WTCP-L Soldering Station

This is a later version of the Weller model W-TCP's above. It's 60 watts and used a 24 volt Weller TCP 1 Magnastat iron

The WTCP-L has a power switch and light. The AC cord is hard wired into the base.

Larger Photo

Service Bulletin

|

|

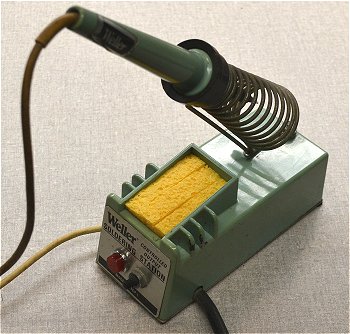

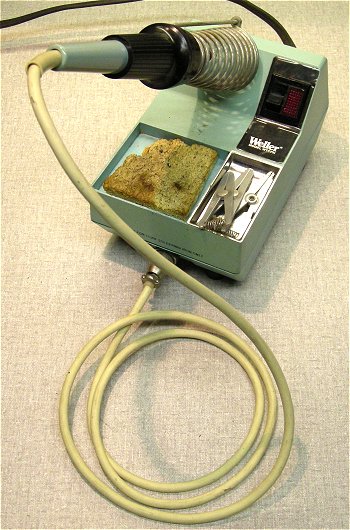

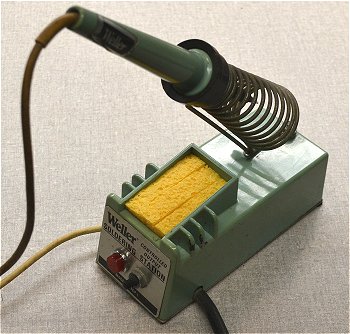

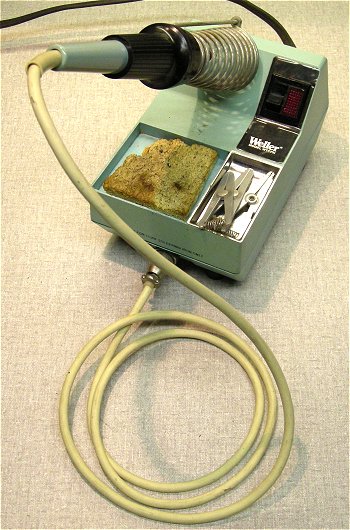

Weller WTCPN Soldering Station

The Weller WTCPN series stations followed the W-TCP series soldering stations. I have used this Weller soldering station

on my bench for 30+ years. It's been through hell and back and works as good as the day I bought it used. I've replaced the cord connector, a few tips, and sponges over the years but this Weller station still gets daily use and does

not let me down. I have newer adjustable soldering stations but this my all time favorite soldering tool.

WTCPN Parts and Tips List

WTCPN Tech Sheet (Service, Parts)

The WTCPN uses the Weller PT series Magnastat type tips.

I normally use a 700 degree 1/8 inch chisel tip for most Lead/Tin alloy soldering jobs.

Each tip is stamped:

6 = 600 Degrees F

7 = 700 Degrees F

8 = 800 Degrees F

|

|

Weller EC2000 Soldering Station

The Weller Temperature Controlled EC2000 Soldering Station adjusts tip temperature from 350 to 850 degrees with

digital display and switch to lock temperature.

Larger Photo

Catalog Listing

EC2000 Tech Sheet (Service, Parts)

|

|

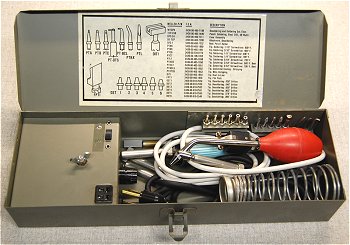

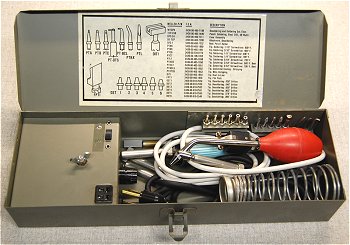

Weller WTCPK Military Soldering Kit

This compact soldering station set manufactured by Weller is enclosed in a steel case. This kit runs on 120 Volts AC but 12 Volt DC kits were also produced. The kit contains a TCP-24G, 24 volt, 42 watt soldering iron, eight soldering tips, holder, several attachments, and a desoldering tool with seven tips.

The iron plugs into the power supply using a 4-pin Jones plug. The holder is fastened to the top of the power supply by a wing nut when in use.

Case: 13" x 4 ½" x 2 ½"

Larger Photo

Case

Cover Parts List

AC Power Supply

In Operation

|

|

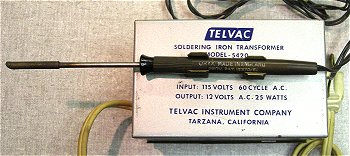

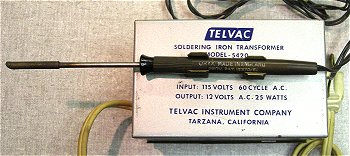

Telvac 5420 Soldering Iron Transformer

This Telvac 5420 Low Voltage Soldering Iron transformer outputs 12 volts AC. It has an English ORYX light duty pencil soldering iron hooked up to it.

From the style of the tip it was probably designed to hand solder surface mount ICs and components.

Larger Photo

|

|

HR Electric Soldering Machine

This HR Superior Electric Soldering Machine is a modern version of the electric soldering machine at the top of this page. It also uses a carbon with current passing through the item being soldered and turns on and off with a foot pedal. I'm pretty sure it's mainly designed for small work like jewelry making.

It has a model number of 42-553 but I don't have any other details on the manufacturer although I have found what looks to be the same unit under many different brand names and offered by jewelry suppliers.

This one looks to be new and never assembled or used. The date stamped inside the chassis is July 25, 1977. There is a price sticker on the box for $104.50. The current ones I have found on line range from $345.00 to $495.00.

I'm not sure I'd operate it after looking inside the case.

Larger Photo

Inside Photo

Instructions

|

|

My latest Soldering Station

For detailed and surface mount soldering I use a

Weller WX-2, 2 Channel Soldering Station

with Small and Medium Tip Pencils, and Tweezers in Stands. |

|

|